KUKA Robotic Nailing: Advanced Automation for Industrial Assembly

Nailing is one of the most fundamental fastening processes in manufacturing. But despite its simplicity, it’s a surprisingly challenging operation to do consistently and efficiently at scale. Whether it’s assembling pallets, crates, furniture frames, or other wooden products, doing it manually remains labor-intensive, variable, and physically demanding.

That’s why manufacturers across industries are turning to KUKA robotic systems, integrated by Robotic Solutions, to automate and modernize this essential step in production.

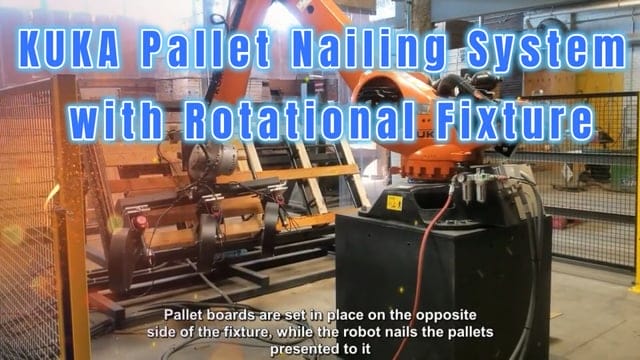

Pallet production is a fantastic use of robotic nailing. Traditionally, building wooden pallets requires manual placement and nailing of deck boards and stringers—heavy, repetitive work that’s hard to staff and prone to error.

The Need for Robotic Automation

Traditional nailing operations suffer from:

- Labor challenges: Hard-to-fill, repetitive, injury-prone jobs.

- Inconsistent quality: Variability in nail placement, depth, or pattern.

- Throughput limitations: Slower production cycles, especially during labor shortages.

- Safety risks: Injuries from misfires, repetitive-motion strain, or handling heavy components.

Robotic nailing automation solves these problems by delivering:

- Consistent, repeatable fastening across every unit.

- Higher production speeds with minimal downtime.

- Improved safety by removing workers from hazardous, tiring jobs.

- Reduced waste and rework thanks to precise, programmable patterns.

How KUKA Robotic Nailing Systems Work

KUKA’s industrial robots offer exceptional flexibility and precision for automated nailing tasks. Integrated by Robotic Solutions into turnkey systems, these robots can be equipped with:

- Pneumatic or electric nailing tools engineered for high-volume production.

- Programmable multi-pattern control for variable products.

- Force sensing to maintain consistent nail depth across different materials.

- Vision or part-location systems for precise placement even with variable part sizes.

These features make KUKA robots ideal for a wide range of assembly tasks, including but not limited to pallet production.

A KUKA robotic pallet cell integrated by Robotic Solutions could:

- Automatically feed and position components.

- Precisely drive nails in pre-programmed patterns.

- Operate safely in enclosed, dust-controlled environments.

- Deliver consistent, high-quality builds with less labor.

But the technology doesn’t stop there. The same approach can be applied to any wood assembly process requiring nailing.

Beyond Pallets: Flexible Automation for Wood and Beyond

While pallet production is a high-volume application, fully integrated KUKA robotic systems excel in many other manufacturing contexts:

- Crates and custom shipping containers

- Furniture frames and subassemblies

- Architectural millwork or structural assemblies

- Prefab construction elements

These robotic cells can be tailored to the size, weight, and complexity of your products. With Robotic Solutions as your integration partner, these systems can be designed to match your production floor layout, part flow, and quality requirements.

Why Choose KUKA Robots for Nailing?

KUKA offers:

- Wide payload range: From lightweight nailing tools to heavy components.

- High precision and repeatability: Critical for reliable fastening.

- Flexible programming: Easily adapt to new products or nail patterns.

- Durability: Built for demanding industrial environments.

Combined with Robotic Solutions’ integration expertise, KUKA robots become the heart of robust, production-ready nailing cells that can revolutionize your manufacturing process.

The Bottom Line

Nailing is essential in manufacturing—but it doesn’t have to be manual, inconsistent, or dangerous. KUKA robot cells, integrated by Robotic Solutions, deliver:

- Consistent, high-quality fastening

- Increased production speed

- Safer, cleaner workplaces

- Flexible production for changing needs

Whether you’re building pallets, crates, furniture frames, or other wood products, robots are a smart investment in the future of your manufacturing operation.

Contact Robotic Solutions today to learn more about how KUKA robots can help you modernize your production line, to discuss our industrial automation solutions and gain a competitive edge. We are here to talk through how we can make a fully customized system for you.

View some of our other demo videos here.

Check out even more videos on our Youtube Channel